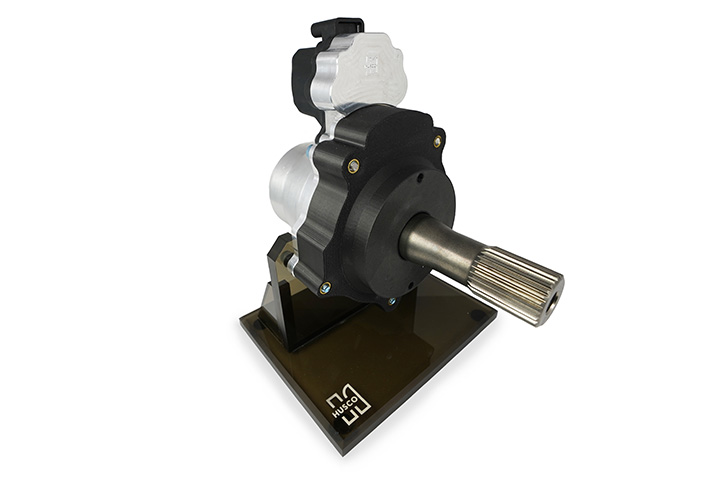

Wheel End Disconnect

Husco’s wheel end disconnect system increases energy efficiency by enabling the disengagement of the electric motor from the wheels. This system increases vehicle range and reduces the total number of batteries required on the vehicle – a win for OEM’s and end users. A disconnect system is an essential feature in electric vehicles that improves performance, provides greater flexibility in the powertrain and increases energy efficiency. The wheel end system (shown here) is one of several disconnect solutions Husco has developed.

Husco’s disconnect systems offer the following competitive advantages:

- Removes all driveline drag when disconnected

- Integrated sensor and optional control

- Bi-stable solenoid technology allows zero power draw in selected positions

- Fast engagement and disengagement response

Download the Spec Sheet to Learn More:

Off-Axis Disconnect

Husco’s off axis disconnect systems leverage proven bi-stable solenoid and motor-driven technology in a convenient bolt-on package. This allows a disconnect system to be used as a side-shaft disconnect mounting to the case of the transaxle between the output of the transmission and the half shaft.

- Convenient Packaging

- Onboard position sensing

- Quiet

- Zero power hold states

Download the Spec Sheet to Learn More:

Ring Solenoids for Disconnect Applications

Husco’s customized offerings of monostable, bi-stable and tri-stable ring coil actuators allow for full in-line integration of disconnect systems within the transmission. Common applications include integrated E-motor disconnects, muliti-speed gear switching, and electric differential lock-up for front or rear axles. Husco engineering expertise will help package and tailor the ring coil actuator to your specific application needs.

- In-line packaging

- Onboard position sensing

- Fast response and quiet operation

- Zero power hold states

- Custom configurable