Husco is excited to announce our participation in Bauma Germany 2025, taking place April 7-13, 2025 in Munich, Germany. Visit the Husco stand to explore our innovative electro-hydraulic cartridges, control valves, and digital systems. Learn how our advanced technology enables precise control, autonomous functions, and enhanced operator control features.

Discover Cutting-Edge Electro-Hydraulic Solutions in booth A3.139

Unique Solutions Built for Your Machine

Husco delivers high-quality, tailored solutions through comprehensive system design, advanced optimization, and bespoke testing to meet each client’s specific needs.

- Husco Solenoid Technology: Our cutting-edge solenoid technology ensures precise control and reliability in various applications, enhancing overall system performance.

- Flexible Packaging Options: We offer a variety of packaging solutions tailored to meet the specific needs of different projects, ensuring optimal integration and functionality.

- Cost-Effective Designs: Our designs are not only innovative but also cost-effective, providing high-quality solutions that deliver excellent value for money.

- Bespoke Circuits & Tuning: We specialize in creating custom circuits and fine-tuning them to meet the unique requirements of each client, ensuring maximum efficiency and performance.

- Total Machine Acumen: With extensive knowledge and experience in machine systems, we provide comprehensive insights and solutions that enhance the overall operation and productivity of your machinery.

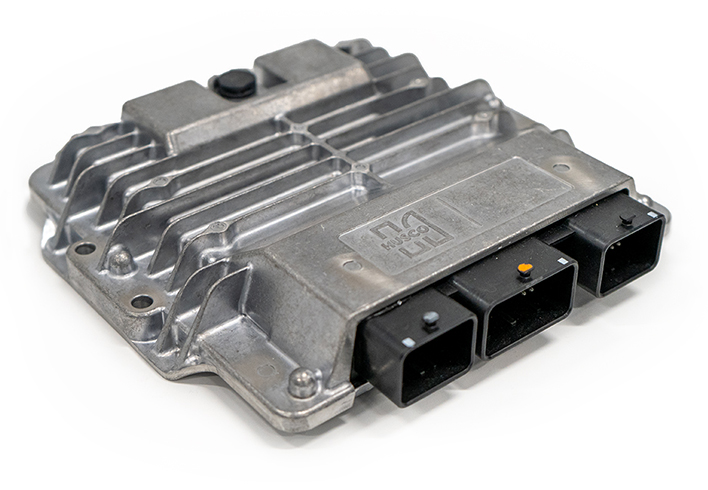

Controllers

Designed to enable easy precise control while providing a unique, futureproof safety and security strategy. These embedded control units meet the rigorous performance and safety demands of mobile machines, offering you a gateway to innovative automation solutions.

- Custom embedded coder targets and hardware support a model-based design approach

- Simple integration of both new and existing control systems within the MATLAB/Simulink environment

- On-machine and in-simulation development allow for accurate management of electro-hydraulic valves and servo systems

- Future-proof design working to comply with upcoming functional safety standards (IEC61508, ISO13849, ISO19014) and cybersecurity requirements

- Code generation fully supported through S-function API libraries supplied with the controller in Simulink

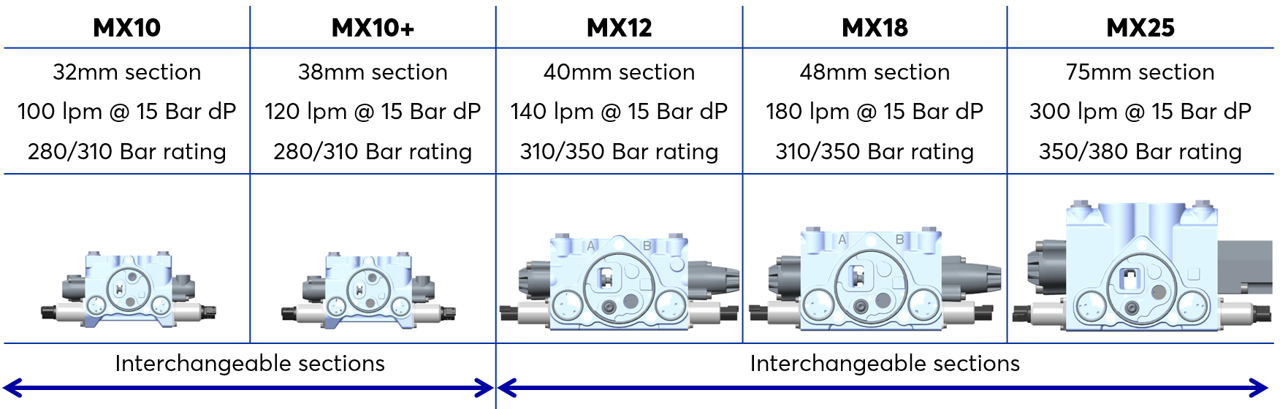

MX Platform

This pressure compensated load sense (PCLS/LUDV) valve platform offers advanced features providing greater flexibility and productivity in a compact space.

- Global platform build for cost-effective and robust electro-hydraulic integration

- Variety of circuits available in the same embodiment to enable progressive upgrades without changing hardware packaging

- Patented SMART priority, providing pressure compensated flow balance

- Built-in pressure compensator bypass gives additional tuning variable to direct power into the functions needed most

- High-efficiency variable regen circuit

- Solutions for excavation, material handling, mining, and other compact applications

Cartridges

Husco’s selection of direct-acting and proportional cartridges is designed for diverse use. Semi-automated and fully automated assembly, testing and packaging processes ensure market-leading quality performance and consistent part-to-part reliability.

Cartridge highlights:

- Superior digital-to-hydraulic control

- Cost effective dual sourced supply chain and global manufacturing strategy

- Wide range of low pressure solutions for a variety of applications

- High pressure size 8 and size 10 complement a variety of hydraulic logic circuits

- Solutions for transmission, engine, work function (main control valve), manifold, as well as a wide range of compact applications

Driveline technologies

Husco’s driveline solutions improve control flexibility and increase energy efficiency.

Brakes

- Service and trailer E-brake options

- Brake assist utilizing Husco’s cost effective cartridge products

- Unique solutions with several brake features such as charge circuit, manual override, sensors integrated into single system

Priority solutions

- Cost-effective integrated and stand-alone priority device technology

- Solutions to optimize various single and multi-level priority and load sense circuits

- OEM specific packaging with flexible tuning parameters and consistent performance

Drive Disconnect

- Removes all driveline drag when disconnected

- Integrated sensor and optional control

- Bi-stable solenoid technology allows zero power draw in selected positions

- Fast engagement and disengagement response

Transmission

- Custom systems for a wide range of applications

- Integrated proportional and on-off control with speed, pressure and temperature sensors within the assembly

- Solutions for clutch, cooling, torque converter, powershift, CVT and ancillary control